|

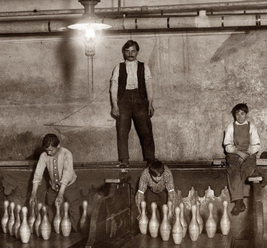

First let me give you a bit of history and how things were done years ago. A bowling establishment hired "Pin Boys" to manually set up the pins, pick up any pins to get them out of the way for the second shot, and return the balls to the bowlers. They made about ten cents a game and about $2.00 on a busy night. There are still a few bowling centers today that have pin boys, believe it or not. This was the case until a man named Gottfried Schmidt invented a machine called the "Pinspotter" in 1936 while being employed with the AMF firm. Then in 1941, he ended up selling the patent to AMF, paving the way for newer and updated pinsetting machines. These pin setting machines were invented around 1963 but now there are computerized machines that have various SENSORS in them. These Sensors can detect the bowling ball as it approaches the pins. Once the ball knocks down the pins, a gate comes down called the "SWEEP". It protects the remaining pins while a "PIN TABLE" is lowered onto the pins that remain, picks them up, and then sweeps the downed pins (called Deadwood) off the pin deck. The pin table counts the number pf pins that remain standing and sends that information to the computer that keeps track of your score. The ball's impact is stopped by the "BALL CUSHION ASSEMBLY" which has enough space for the pins to go through but not the ball. Once the deadwood is cleared off of the pin deck, those pins and the bowling ball are transported onto a conveyor belt below. The ball pit also has a sensor that opens the ball door a few seconds after the pins have been cleared off of the conveyor belt. This area has a BALL ACCELERATOR which pushes the ball along a track under the lane and is what brings the ball back to the ball return. Once the pins are cleared off the conveyor belt, they are taken up separately to the pinsetter by a little elevator that has slots or shelves holding each pin in place. These slots tilt to push the pins off and each pin hits a PIN COUNT SWITCH so only ten pins go into the Distributor. The pins are guided on tracks that have little SHARK FINS that guide the pins to the right or left side of the machine. There are TURN WEDGES that turn the pins so their bottom is always facing downwards. Each pin is then sent to a PIN STATION, and once all ten pins are set and extra pins go into the OVERFLOW CHUTE and back down to the conveyor belt and back up to the elevator. Each pin setting machine can hold up to 20 bowling pins so they can get into the slots and back into the pin table quickly when you hit the re-set button by the ball return. If you want to see a pin setting machine in action, you can go online and watch a Youtube video if you'd like. I just thought it was interesting to see how the pins actually got set up so quickly and thought you might enjoy this as well. Don't forget to check before throwing your first shot, that all ten are up there and that the rows look even. Sometimes pinsetters can be off slightly and only put 9 pins up there. Once you throw the ball, if you notice all ten pins were not up there, it will be too late and it could cost you a strike. I f a pin is missing or something doesn't look right on the pin deck to you, you are allowed to have a re-rack. Just hit the re-set button. Join me back here again next week when I'll be discussing some of the other Oil Patterns used in Bowling. As always, Good Luck and High Scoring!!

0 Comments

Leave a Reply. |

AuthorHello!! My name is Joanie. Although I'm not a professional bowler, I have loved the sport for more than 45 years, averaged over 200 for several seasons, and learned quite a bit with research and experience. Archives

February 2023

Categories |

RSS Feed

RSS Feed